HOME *

DUSTY'S PAGE

* THE HOUSE

* THE HANGAR and

MORE HANGAR STUFF and

HANGAR DETAILS

* THE AIRPLANE

ODDITIES AND HOBBIES

and even MORE HOBBY

STUFF * HUMOR * FAVORITE

LINKS * AMSOIL

PRODUCTS

I created these pages as construction progressed in December of 1999, I have been in the completed hangar for four years now. What follows is the text and pics as I entered them during the construction of the hangar.

***

I've been planning for more years than I can count for a hangar behind a house on an airstrip, and now it is finally coming together. I will be adding to this page constantly as the construction progresses.

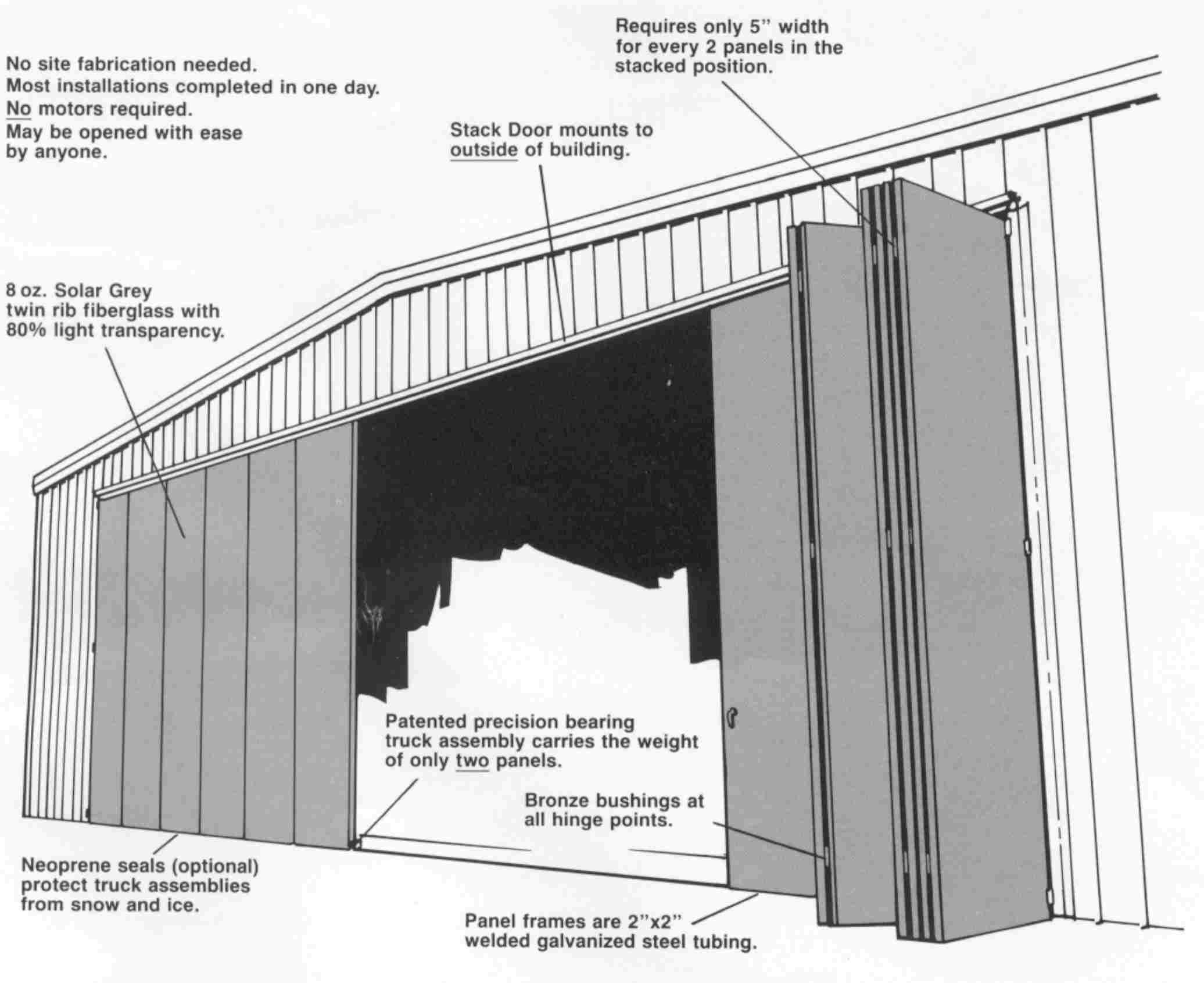

The hangar will be located 80ft behind my house and will face the taxiway (east), which is about 200ft away, down a gentle slope. The construction will be a conventional metal building, 60x60ft with a 16ft high eave and a 12/2 pitch roof. It will have 14ft high by 53ft (when open) Horton Stack Doors. These doors open like the bifold doors on your bedroom closet. There will be a 12ft wide by 14 ft high roll up door in the "back" of the hangar, which is the end facing the house. There will also be a walkthru door in the back. On the north side of the building will be a walk thru door and a 10x10ft roll up door. These doors are placed here as I intend to later add on to this side of the building and they will provide access into the addition.

The building will be manufactured by Metal Buildings, Inc. (MBI) (also operating under the name of BSX, Building Systems Express) of Thomasville, GA [call Mr. Bill Inman at 1-800-279-9455] and the slab and erection will be handled by Evander Lowery of Lowery Construction of Rocky Mount/Luthersville, GA. [you can reach Evander in the evenings at 770-927-6460] This is a custom building in that it has a 12/2 roof pitch, whereas most metal buildings have a 12/1 pitch. The extra pitch was done to help match the relatively steep pitch of the house roof. Also water will drain off faster and better and the roof will be less likely to leak at a screw or seam.

The order for the building was placed September 16, 1999 and the last details finalized on October 6, 1999

Below are a couple of photos of the form boards and such in my backyard

where the hangar is being built. (Last week of October '99)

(BELOW) Here is the pouring of the slab, November 3rd., '99

(BELOW) Pouring at the front of the building, the door track channel is attached to the formboard. Thats my contractor, Evander Lowery, bent over rapping the form with a hammer to make the voids fill with concrete. It must work as there were no voids anywhere along the 240 ft perimeter of the slab.

(BELOW) The slab is finished!!!! The forms have been removed and the footers backfilled and a couple of coats of sealer put on it. All that it needs is to bolt down a building and its done! Then comes the landscaping.! By the way the airplane fuselage in the photo is a scrap one I've been salvaging parts off of.

(BELOW) This is a building???? (November 17, '99, the building arrives)

(BELOW) Here I have included a couple of illustrations clipped out of the Horton Stack Door brochure so you can have some idea of what the doors will look like when they are installed. Visit the Horton web site at http://www.hortonstolcraft.com/horton_stack_door.htm for more information on these wonderful doors. If you go to http://www.hortonstolcraft.com/ you can see all of Horton's other aviation products.

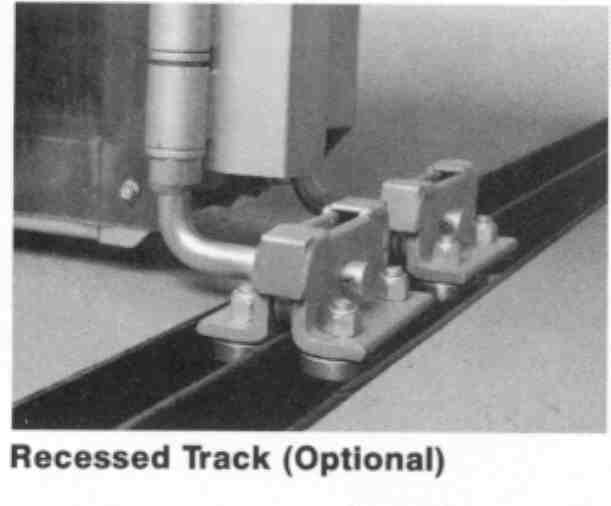

(BELOW) This is the door roller carriages in the recessed track. To give you an idea of size, thats a 4 inch wide channel with a 1.5 inch angle iron welded in the middle of it. Each carriage is about 3 inches by 4 inches.

(BELOW) December 1st, '99, Things finally start happening. This is the middle of the first day, Typical snafus, anchor bolts that don't quite fit, a couple of misfit parts, but its looking like a building.

(BELOW) December 2ed, '99, now it really is a building, just doesn't have its skin. We are late in day two now and have had a couple of more snafus but things are still going along OK.

(BELOW) Speaking of SNAFUS, this is one of the worst we had, it seems the building manufacturer welded the tabs (on the outside of the six mainframes for the top purlin, not the eave) one foot too high, but drilled the back corner columns where they were supposed to be. The problem was solved by redrilling the back corner columns one foot higher and moving the purlin attach clips up. The building manufacturer's engineers OK'ed this.

(BELOW) On Dec. 3rd, '99, the South wall was sheeted (that's the wall to the left) and on Monday Dec. 6th the North wall was sheeted, and on Tuesday the 7th the back wall was done. On Wed, Dec. 8th, '99, the entire roof was done, there were more workers on the job is the main reason such a large area was done so quickly, also the slightly warmer weather helped.

Here is the building on Tuesday afternoon, the 7th.

(BELOW) Here is the building midday on the 8th, with the roof about half done. It was finished when the crew left about 5 PM.

IF YOU WOULD LIKE TO SEE PAGE 2 OF THE HANGAR, WHICH BEGINS WITH THE COMPLETE, BUT STILL OPEN BUILDING, CLICK HERE.